Equipment Cost per Hour Calculator

Calculate precise hourly costs for construction equipment to bid jobs accurately and maximize profits.How Equipment Cost per Hour Calculator Works

This calculator determines the hourly cost of operating construction equipment by dividing the total equipment cost by the number of hours used. Whether you bought a $50,000 excavator or a $5,000 power tool, knowing your exact hourly cost is crucial for accurate job bidding.

Construction contractors use this calculation to ensure they're covering equipment costs in their project bids. It helps you understand what it actually costs to operate your equipment per hour, which is essential for profitability. Many contractors fail to properly account for equipment costs and end up giving away expensive equipment usage for free.

The calculation works for any type of equipment - from heavy machinery like bulldozers and cranes to smaller tools like generators and compressors. You can use actual purchase costs for owned equipment or rental costs for leased equipment to get your baseline hourly rate.

Equipment Cost per Hour Calculator Formula Breakdown

Formula

Equipment cost per hour = Total equipment cost ÷ Number of hours usedVariables Explained

- Total equipment costThe total cost associated with the equipment, which could be the purchase price for owned equipment, rental cost for leased equipment, or operational cost for a specific period. For owned equipment, you might include purchase price, financing costs, insurance, and maintenance expenses.

- Number of hours usedThe total hours the equipment will be or has been in operation. This is typically measured over the equipment's useful life, a specific project duration, or billing period. Accurate hour tracking is essential for precise cost calculations.

Example Calculation

Given:

- Total equipment cost: $5,000

- Number of hours used: 40 hrs

Calculation:

Equipment cost per hour = $5,000 ÷ 40 hours = $125.00 per hourResult:

$125.00 per hourExplanation

This example shows the hourly cost for a $5,000 piece of equipment (like a generator or compressor) used for 40 hours. At $125 per hour, you'd need to charge at least this rate to your projects to break even on the equipment cost, before adding markup for profit and overhead.

Tips for Using Equipment Cost per Hour Calculator

- 💡Track equipment hours meticulously using daily timecards or hour meters to ensure accurate calculations and proper job costing.

- 💡For owned equipment, include all costs of ownership (purchase price, insurance, maintenance, fuel, transportation) rather than just the initial purchase price for more accurate hourly rates.

- 💡Add a markup of 15-25% to your calculated hourly rate to account for overhead expenses and generate profit on your equipment investment.

Make Your Own Web Calculator in 3 Simple Steps

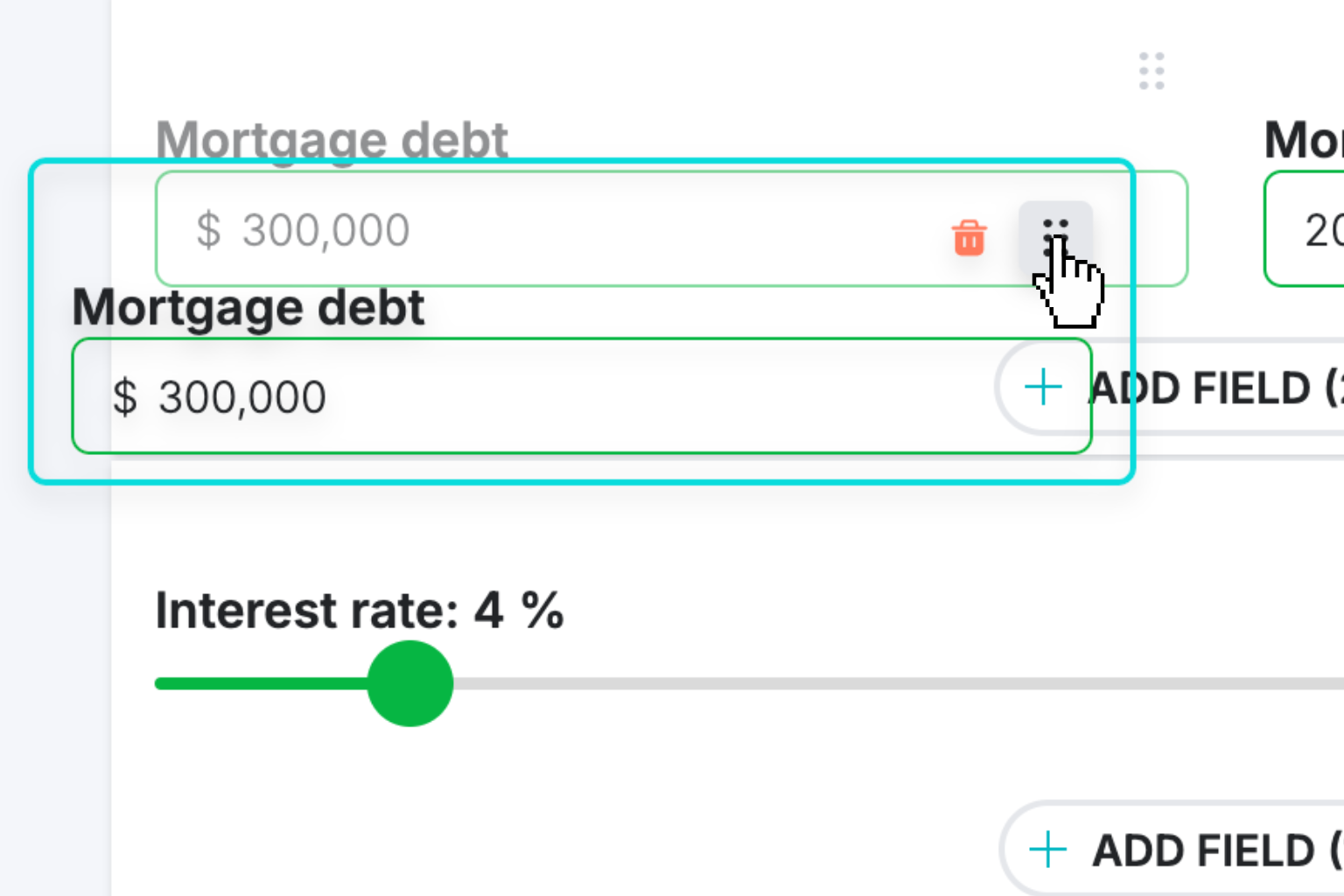

Create Interactive Calculator

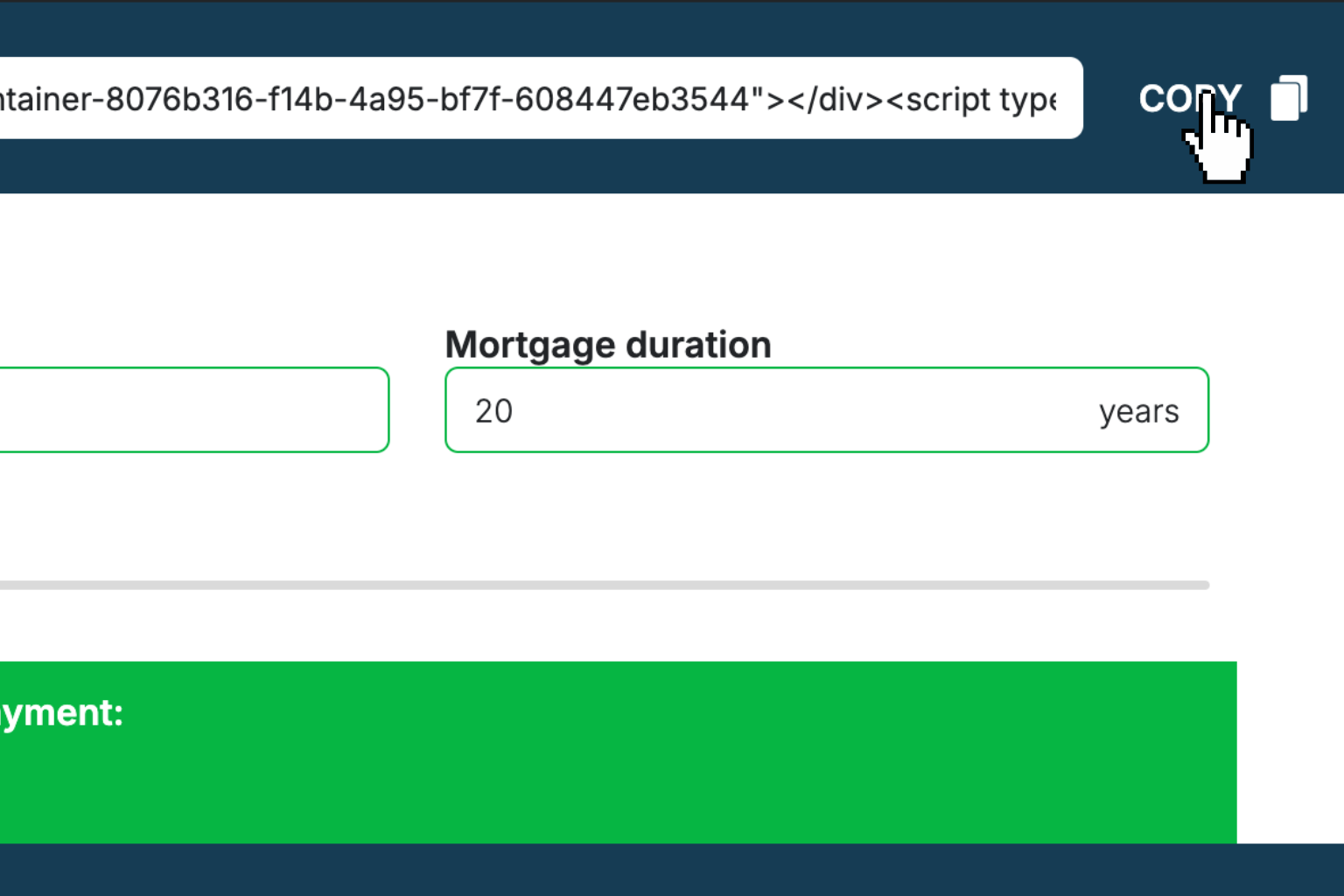

Design your interactive calculator in under 5 minutes using our drag-and-drop builder.Preview & Generate Embed Code

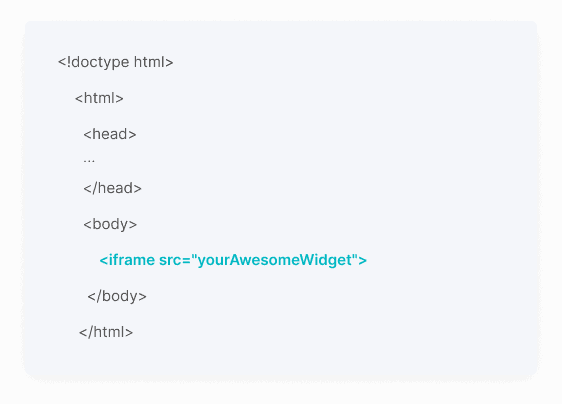

Review your calculator and copy the embed script when you're satisfied with the results.Embed Calculator Into Your Website

Paste the code into your website's HTML. Works on WordPress, Shopify, Wix, and any platform.

Eugen

Creator of Creative Widgets“After 10+ years in digital marketing, I’ve built calculators that drove thousands of new leads for clients. I realized one thing: calculators convert. They're killer for CRO and great for SEO. That's why I built Creative Widgets—an easy, no-code calculator builder. ”

It's free. Try it out. You'll like it.