Resin Calculator

Calculate exactly how much resin you need for molds, castings, and epoxy projects.How Resin Calculator Works

This calculator figures out the exact volume of resin needed for your project based on the shape and dimensions you enter. Whether you're working with rectangular molds or cylindrical objects, it handles the math for you.

The tool accounts for resin loss allowance - that inevitable waste from mixing, spillage, and what sticks to your tools. You can adjust this percentage based on your experience level and project complexity.

Once you know the total volume needed, the calculator breaks down the exact amounts of resin and hardener to mix based on common ratios like 1:1, 2:1, or 3:1. This ensures you get the right cure every time without guesswork.

The results help you buy the right amount of materials upfront, avoiding expensive rush orders or wasted leftover resin that might expire before your next project.

Resin Calculator Formula Breakdown

Formula

Volume calculation: For rectangles = Length × Width × Depth; For cylinders = π × Radius² × Depth

Total resin needed = Volume × (1 + Loss allowance percentage)

Resin amount = Total needed ÷ (1 + hardener ratio)

Hardener amount = Total needed - Resin amountVariables Explained

- ShapeWhether your project is rectangular (like a tabletop or casting mold) or cylindrical (like a pipe or round container). This determines which volume calculation formula to use.

- LengthThe longest dimension of your rectangular project in inches. For casting molds, measure the inside dimensions where the resin will go.

- WidthThe shorter horizontal dimension of your rectangular project in inches. Always use inside measurements for molds and containers.

- RadiusHalf the diameter of your cylindrical project in inches. For round molds or containers, measure from the center to the edge of the inside surface.

- DepthHow thick you want your resin layer or how deep your mold is in inches. This is the vertical dimension that determines the volume of resin needed.

- Resin loss allowanceExtra percentage added to account for waste, spillage, and resin that sticks to mixing tools. Beginners typically use 10-15%, while experienced users might use 5-10%.

- Resin to hardener ratioThe mixing ratio specified by your resin manufacturer. Common ratios are 1:1 (equal parts), 2:1 (two parts resin to one part hardener), or 3:1 (three parts resin to one part hardener).

Example Calculation

Given:

- Shape: Rectangle

- Length: 12 in

- Width: 20 in

- Depth: 5 in

- Resin loss allowance: 10%

- Resin to hardener ratio: 1:1

Calculation:

Volume = 12 × 20 × 5 = 1,200 in³

Volume conversion = 1,200 ÷ 1.805 = 664.54 fl oz

Total with loss allowance = 664.54 × (1 + 10%) = 731.00 fl oz

Resin amount (1:1 ratio) = 731.00 ÷ 2 = 365.50 fl oz

Hardener amount (1:1 ratio) = 731.00 ÷ 2 = 365.50 fl ozResult:

731.00 fl oz total mixed resin neededExplanation

This example shows calculating resin for a rectangular casting mold, like making a decorative concrete countertop or large resin art piece. The 10% loss allowance accounts for resin that sticks to mixing tools and potential minor spillage.

Tips for Using Resin Calculator

- 💡Always measure inside dimensions of molds and containers - not the outside thickness of the walls.

- 💡Start with 10-15% loss allowance for your first few projects, then adjust based on your actual waste patterns.

- 💡Buy slightly more than calculated rather than running short mid-project - partially cured resin won't bond well with fresh batches.

Make Your Own Web Calculator in 3 Simple Steps

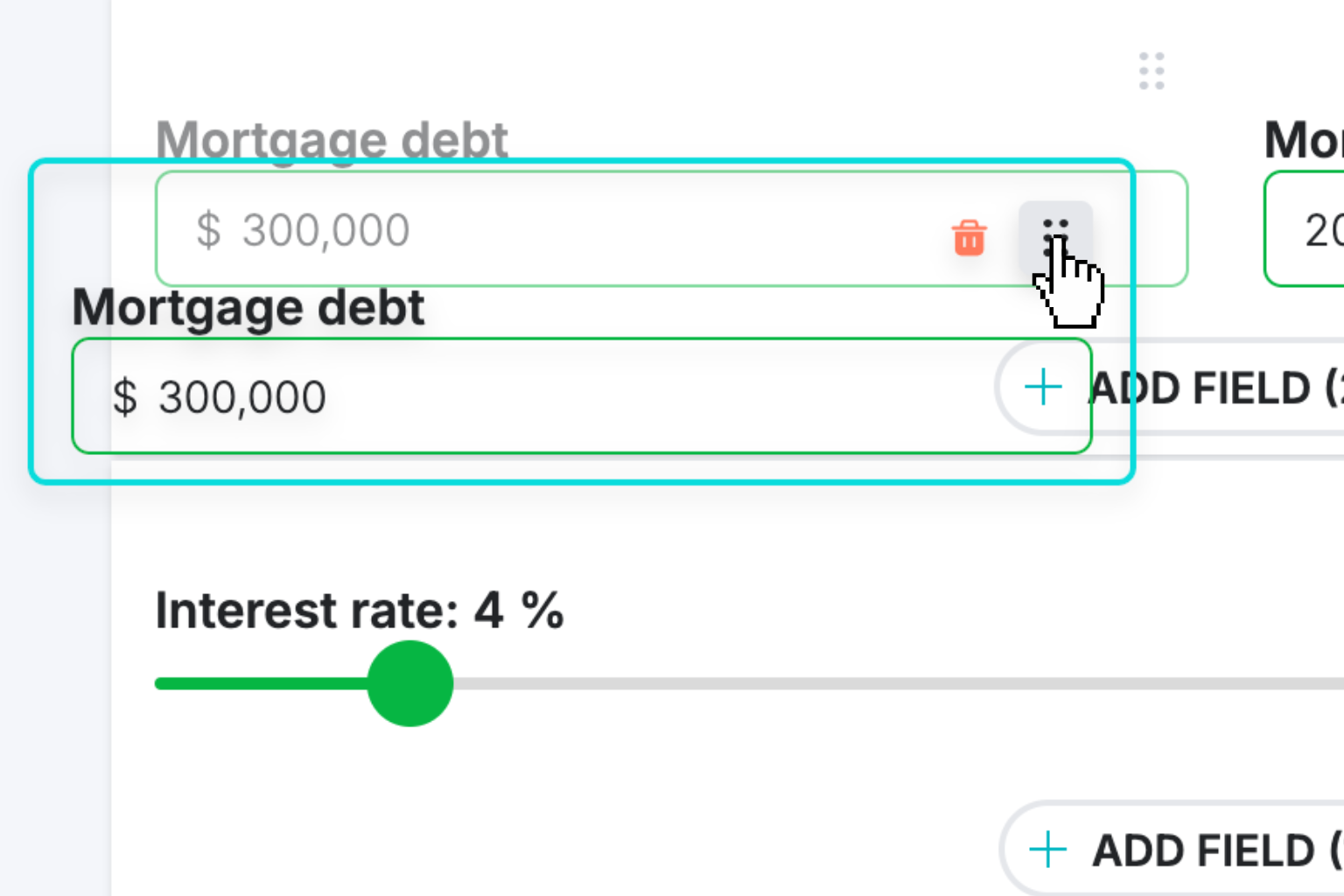

Create Interactive Calculator

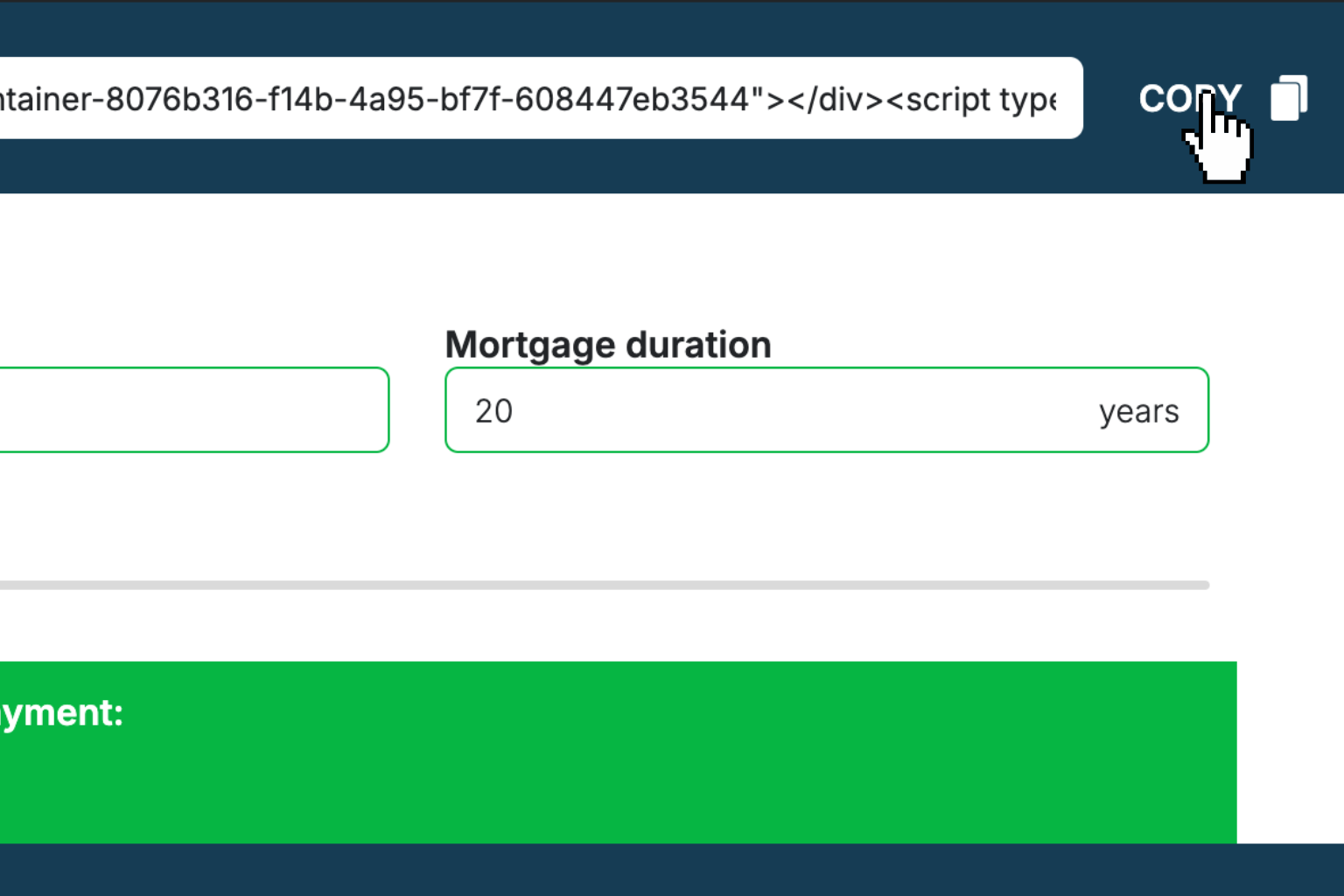

Design your interactive calculator in under 5 minutes using our drag-and-drop builder.Preview & Generate Embed Code

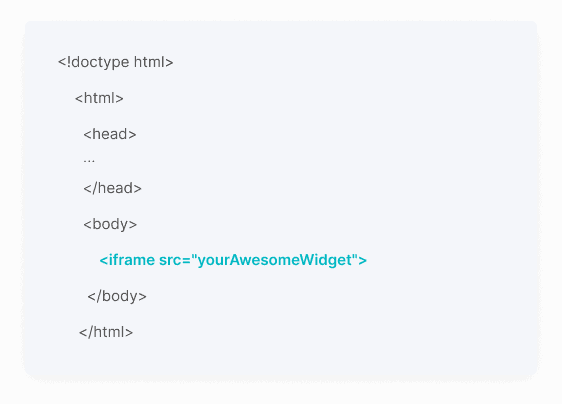

Review your calculator and copy the embed script when you're satisfied with the results.Embed Calculator Into Your Website

Paste the code into your website's HTML. Works on WordPress, Shopify, Wix, and any platform. EugenCreator of Creative Widgets

EugenCreator of Creative Widgets“After 10+ years in digital marketing, I’ve built calculators that drove thousands of new leads for clients. I realized one thing: calculators convert. They're killer for CRO and great for SEO. That's why I built Creative Widgets—an easy, no-code calculator builder. ”

It's free. Try it out. You'll like it.